HomeServices

EQUIPMENT

Equipment

TECHNOLOGY

Core Technology

We specialize in Lip Die and Micro Gravure roll-to-roll precision coating. We can

accommodate high-thickness, ultra-thin, high-precision, and optical-grade products.

With extensive experience in ODM/OEM coating production, our company can swiftly

transition our client’s products into mass production.

01

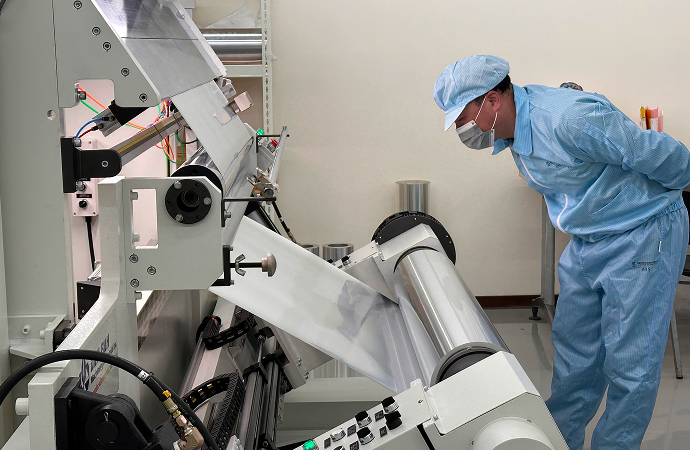

Coating

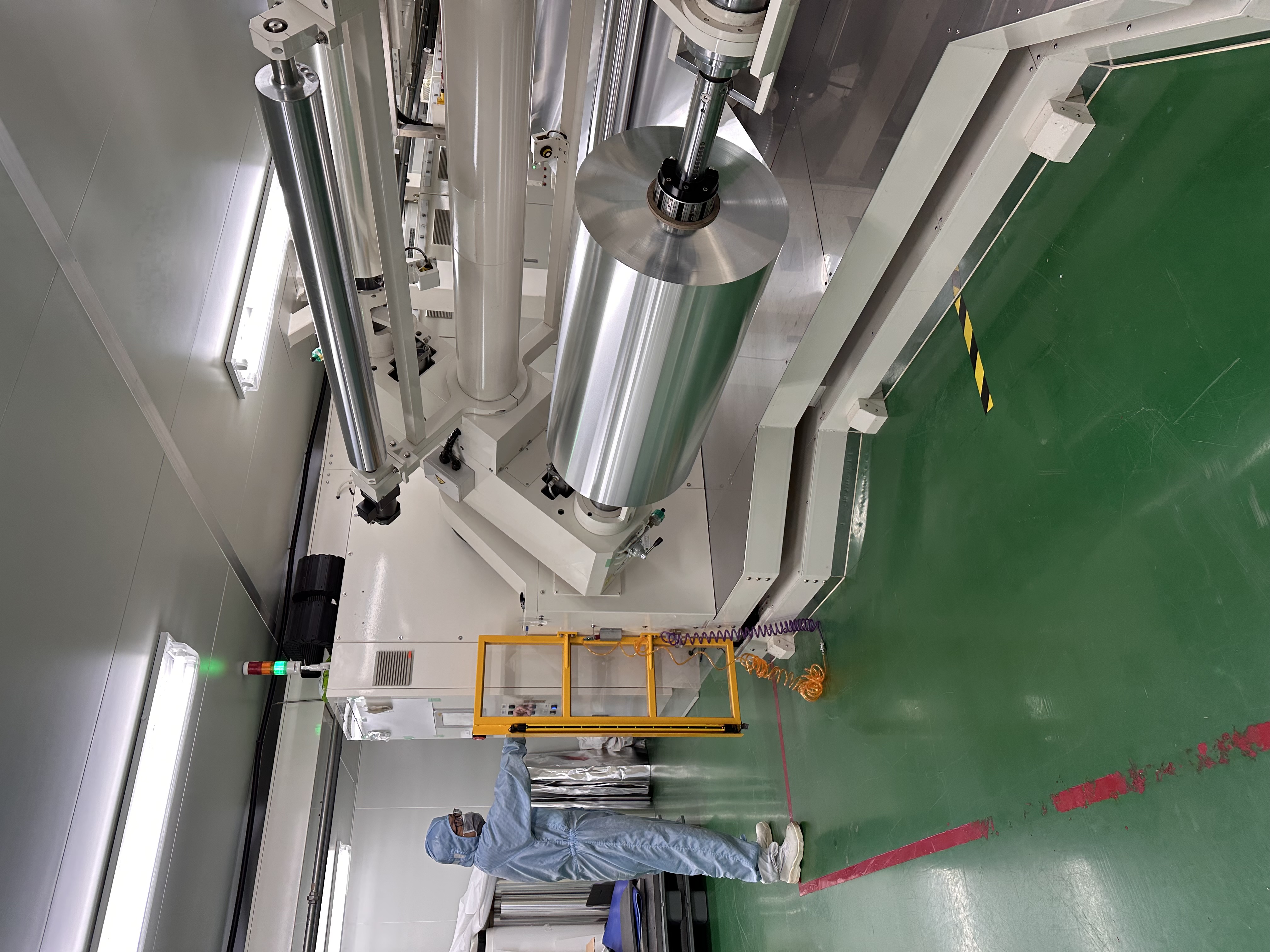

Coating Machine

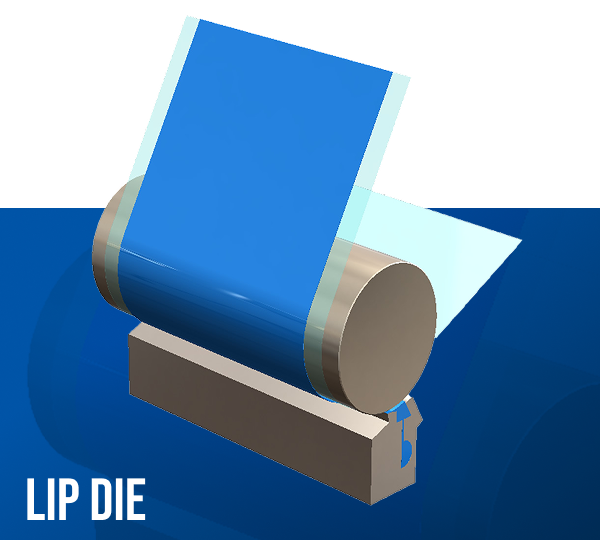

LIP Die Coating

- Utilizing LIP (Liquid Interface Process) technique, the coating is evenly distributed upon the substrate surface, which enhances its surface functional properties.

- Suitable for high-precision coating needs, ensures stable product performance.

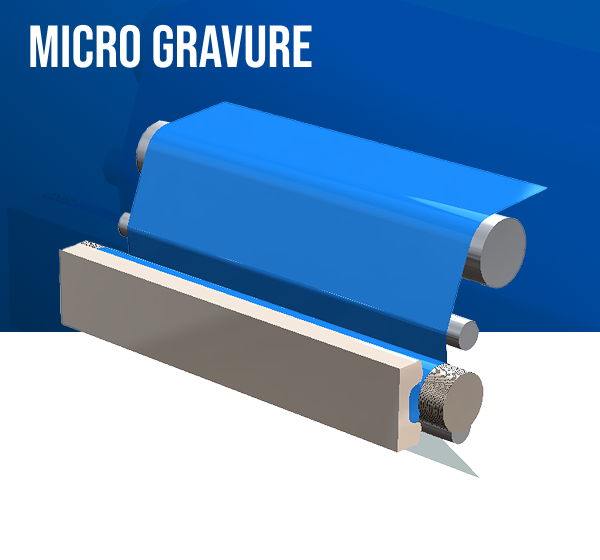

Micro Gravure Coating

- Micro Gravure is a contact-based coating method, where the adhesive is applied using a gravure roller, scraped off, and transferred onto the substrate.

- A variety of gravure rollers are available to meet various applications

02

Lamination

Lamination Machine

- Precision pressure laminating technique firmly bonds the product to ensure a high-strength composition.

- Suitable for various adhesives and metal substrates, enhancing the the product’s overall performance.

03

Slitting

Automatic Slitting Machine

- The slitting process precisely cuts aluminum foil and other substrates to ensure accurate dimensions, and clean-cut edges.

- Suitable for processing aluminum foil, copper foil, and plastic films in various thicknesses and widths.

04

Cutting

Automatic Cutting Machine

- Precision cutting process ensures accurate dimensions, and clean-cut edges.

- Capable of processing various types of thin rolled materials, aluminum sheet rolls, copper sheet rolls, plastic film rolls, and etc.

TECHNOLOGY

Advantages

High-Precision Production

Advanced equipment and stringent quality control ensure quality in every production process.

Customizable Services

Professional services and OEM/ODM solutions tailored to customer needs.

Expert Technical Team

With years of industry experience, we provide the best solutions.